Introduction

A Fire & Gas (F&G) Mapping Study is a critical component of functional safety engineering, primarily used in high-risk industries such as oil & gas, petrochemicals, LNG, and power generation. The objective of an F&G Mapping Study is to assess the optimal placement and effectiveness of fire and gas detectors to ensure early detection, minimize risks, and meet performance targets defined in Safety Integrity Level (SIL) studies and corporate HSE standards.

Objectives of F&G Mapping

The primary goals of an F&G Mapping Study include:

• Ensuring Adequate Coverage: Identifying detector locations that provide maximum area and volume coverage.

• Optimizing Detector Quantity: Avoiding over-design while ensuring sufficient redundancy and functional reliability.

• Compliance with Standards: Meeting international safety standards like IEC 61511, NFPA 72, and ISA TR84.00.07.

• Evaluating Detection Performance: Quantifying detection coverage using tools and models to validate detector layout against defined risk scenarios.

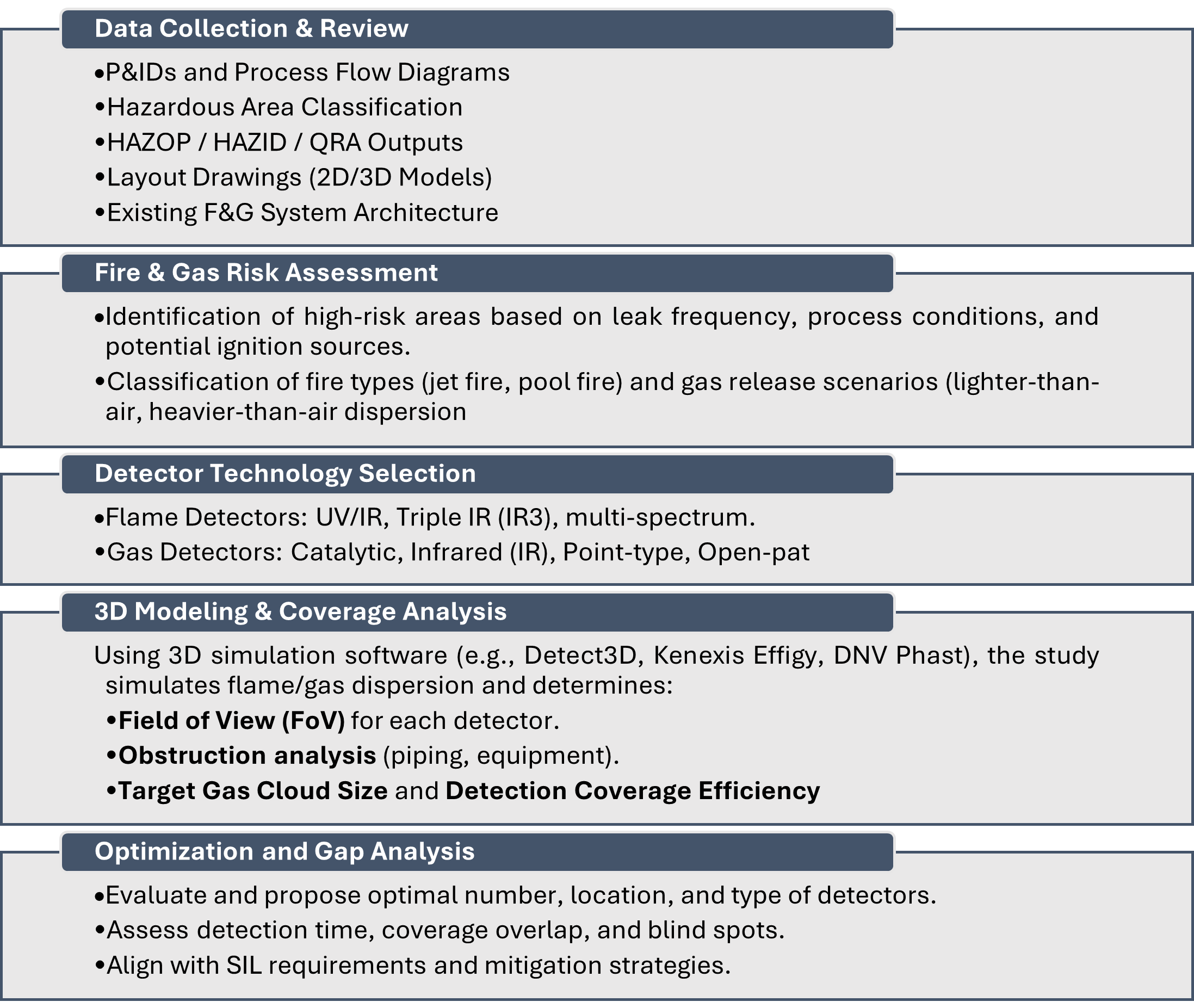

Protocol

An effective F&G Mapping Study typically involves the following steps:

Deliverables

A comprehensive F&G Mapping Study typically provides:

• Detector layout drawings and 3D model visuals.

• Coverage analysis reports (tabular and graphical).

• Recommendations for improving coverage.

• Compliance matrix with standards and client specifications.

• Justification for each detector’s placement.

Benefits of an F&G Mapping Study with Techniche Engineering

• Enhanced Safety Assurance

Through precision-driven detector placement and advanced 3D modelling, Techniche Engineering ensures early detection of fire and gas leaks, significantly reducing detection gaps in critical areas.

• Optimized Cost Efficiency

By avoiding over-design and focusing on risk-based coverage, Techniche Engineering helps clients minimize capital expenditure while maintaining high safety standards — delivering smart and scalable F&G solutions.

• Robust Regulatory Compliance

Our studies are aligned with global safety codes such as IEC 61511, NFPA 72, and OISD guidelines, ensuring audit readiness and full regulatory compliance for your facility.

• Operational Integrity & Reliability

Techniche Engineering’s mapping studies support long-term system integrity through strategic detector placement, which enhances preventive maintenance planning and reduces the risk of false alarms or detection failures.

Conclusion

In high-hazard environments, a well-executed Fire & Gas Mapping Study is not just a design requirement—it’s a life-saving strategy. By leveraging risk-based placement, advanced simulation tools, and performance-based engineering, industries can significantly improve detection reliability while maintaining operational efficiency.

FAQs for F&G Mapping

Q1: What is F&G Mapping in industrial safety systems?

A: F&G Mapping, or Fire and Gas Mapping, is a risk-based technique used to determine optimal placement of fire and gas detectors in hazardous facilities to ensure maximum coverage and safety.

Q2: Why is F&G Mapping important in oil and gas industries?

A: F&G Mapping ensures effective hazard detection, minimizes the risk of undetected gas leaks or fires, and enhances the reliability of emergency shutdown systems in oil and gas plants.

Q3: What are the key components of a fire and gas detection system?

A: Key components include gas detectors, flame detectors, heat detectors, alarm systems, control panels, and F&G Mapping software that simulates coverage and hazard zones.

Q4: How is detector coverage optimized using F&G Mapping software?

A: Advanced F&G Mapping tools simulate detector coverage using 3D models, identifying gaps and ensuring compliance with industry standards like ISA TR84.00.07 and IEC 61511.

Q5: What standards govern F&G Mapping design and compliance?

A: F&G Mapping should comply with standards such as ISA TR84.00.07, NFPA 72, and IEC 61511, which provide guidelines for performance-based safety and functional design.

Q6: What are the benefits of using 3D F&G Mapping?

A: 3D F&G Mapping enhances accuracy in detector placement, visualizes gas dispersion, improves detection efficiency, and reduces false alarms in complex industrial layouts.

Q7: How often should F&G Mapping be reviewed or updated?

A: It should be reviewed annually or whenever there are changes in plant layout, process conditions, or safety regulations to ensure continued hazard detection effectiveness.

Q8: Can F&G Mapping reduce the number of detectors required?

A: Yes, optimized mapping can ensure maximum coverage with fewer detectors, reducing costs while maintaining safety and compliance.

Q9: What industries use F&G Mapping the most?

A: F&G Mapping is widely used in oil and gas, petrochemical, chemical processing, power plants, and other high-risk industries requiring continuous monitoring of flammable or toxic gases.

Q10: How does Computational Fluid Dynamics (CFD) support F&G Mapping?

A: CFD modeling is used to simulate gas dispersion patterns and evaluate detector placement for realistic fire and gas scenarios in varying environmental conditions.

Need help with F&G Mapping for your next project?

Contact Techniche Engineering for expert consultation and design support.

.png)